Reliable Motion Control with Precision Sliding Cables

Smooth, reliable motion control for linear applications. Designed for precise push-pull operation in demanding environments.

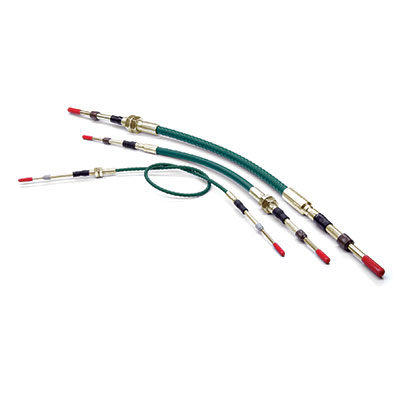

Push-Pull Cables and Controls

Used in applications requiring the transmission of forces in both the push and pull mode of operation. The vast majority of these products use various combinations of conduit styles and solid wire cores in their construction.

Pull-Pull Cables and Controls

Our wide variety of core wire, conduit, conduit fittings, clamps, and accessories offer many design options for the creation of custom cable control assemblies.

Engineering Resources & Design Guides

Our engineering team has applied their years of industry experience to develop resource documentation for each of our product lines.

Cable Assembly Network

Our Worldwide Cable Assembler Network can help you with your mechanical motion control solutions.

Online Catalog

Don’t need a custom design? Download our digital catalog to see all of our available cable and linkage assemblies.

What Are Sliding Control Cables?

Sliding control cables consist of a durable inner core and protective outer conduit, engineered to transmit linear motion effectively. The inner core, typically made of woven wire strands, slides within the conduit to provide controlled, bi-directional motion.

Built for high load capacity and flexible routing, sliding control cables are ideal for applications with complex configurations, heavy loads, or high-tension demands.

Key Benefits:

- Smooth, precise motion

- High load-carrying capacity

- Flexible routing capabilities

- Low-maintenance and long service life

- Corrosion-resistant materials available

Prototypes

Prototypes are available and are an invaluable way to finalize the dimensional and tolerance requirements of any assembly. Life cycle and durability testing can also be conducted on prototypes, prior to production. Contact us to request a prototype.

Industries

Cablecraft is about putting control safely into the hands of the world’s drivers, pilots and equipment operators.

Featured Case Study

Industry: Marine Recreational

Company Type: Marine Propulsion System Manufacturer

Location: Fond du Lac, Wisconsin

Challenge:

Friction issues due to the distance between boat controls at the front and the engine at the rear, leading to substantial wear and shortened system life.

Solution:

- Development of a patented cable assembly featuring:

- Inner member cable extruded with a lubricating material in a polygonal shape to reduce friction

- Outer conduit tubing made with complementary lubricating material

- Injected lubricant providing lifetime lubrication

- Durable outer jacket for added durability

Superior column strength ensuring precise and responsive control.

Outcome:

The solution not only resolved the technical challenges but also surpassed the American Boat and Yacht Council (ABYC) P-14 Cable requirements, offering the client a significant competitive advantage in the marine propulsion market.

Technical Specifications

For Push-Pull and Pull-Pull Cables

Travel Range

Typically between 1 to 6 inches, depending on the specific cable model.

Load Capacities

- Push Load: Up to 125 lbs.

- Pull Load: Up to 230 lbs.

Operating Temperature

- Input End: -65°F to +165°F

- Output End: Up to +230°F

Minimum Bend Radius

As tight as 3 inches, allowing for flexible routing in confined spaces.

Construction Materials

- Inner Member: Nylon-covered or PTFE-coated for low friction and durability.

- Conduit: Plastic-covered, often reinforced with high-tensile steel wires for added strength.

- End Rods and Support Tubes: Options include plated steel or stainless steel for corrosion resistance.

Sealing

Equipped with wiper seals to protect against environmental contaminants, enhancing longevity.

End Fitting

Available in various configurations, including threaded and grooved options, to suit different application requirements.

Construction

- Utilizes flexible stranded steel cable for efficient tension force transmission

- Encased in a protective conduit to shield against environmental factors

Applications

- Throttle controls

- Brake systems

- Clutch mechanisms

- Other systems requiring tension-based motion control

Design Features

- Engineered for environments where only pull forces are applied.

- Flexible design allows routing through complex paths

Custom Solutions Available

Have a unique application? Work with our engineers to design a control cable system that meets your exact requirements.

Engineering Resources & Design Guides

Our engineering team has applied their years of industry experience to develop resource documentation for each of our product lines.

Cable Assembly Network

Our Worldwide Cable Assembler Network can help you with your mechanical motion control solutions.

Online Catalog

Don’t need a custom design? Download our digital catalog to see all of our available cable and linkage assemblies.