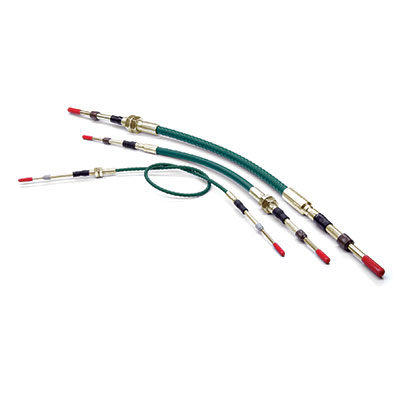

Control Cables - Push-Pull Cables

Cables designed with sold wire cores are used in applications that require the transmission of forces in both the push and pull mode of operation. The vast majority of these products use various combinations of conduit styles and solid wire cores in their construction. Solid wire cores can be formed on the ends to eliminate the need to apply separate fittings or terminations. Bend radii should be large and routing must be simple in order to avoid a permanent set in the core wire.

Push-Pull Cable Controls

All design considerations for push-pull cables also apply when using in combination with any of our controls. Additional cable manufacturing factors do affect the design of these products. They include the molded conduit fittings, conduit selection, assembly function and dimensions. Recognition of these factors, combined with a practical design for the application, will result in a successful, reliable and cost-effective custom cable assembly.

As the design leader in push-pull cables and controls, Cablecraft has provided engineered solutions for a myriad of applications throughout our history. Let our experts design a customized push-pull solution for your unique application or use our design information below to get started.

Fittings

Cablecraft offers a wide variety of standard cable end-fittings which simplify the design process saving you time to market and minimizing development costs. We offer both zinc die-cast fittings as well as steel fittings. Our Engineering team will also design the correct custom cable fittings to meet any unique or proprietary design requirements.

The use of these components, combined with cable specifications and technical information provided in our Engineering Resources, gives the designer flexibility in solving many unique functional problems.

Push-Pull Cable Specifications

Cablecraft uses only the highest quality stranded push-pull cable material to meet your unique requirements. All of our cable is “Commercial Grade” and is constructed to exact quality standards to meet all specifications for flexibility, size and minimum breaking strength.

Use our Engineering Resources to choose the right cable for your application. It will be necessary to match the correct OD of the cable with the proper ID of the conduit allowing for an acceptable amount of tolerance. Use our Control Cable Design Guide to aid you in making the proper selection.

CONDUITS

Every control cable assembly application has unique requirements. Cablecraft offers a full line of conduit choices to meet your specific needs. Whether it’s flexible routing with good compressive strength or a more rigid application with good crush resistance, Cablecraft has the right conduit for you. Our conduits include Braided, Round Wire and Flat Wire Bowden, Long Lay and reinforced Long Lay. Optional liner materials are also offered to meet your application requirements.

Cablecraft offers both shuttle-molded and steel conduit fittings which can be combined with our standard controls and actuators to create a reliable and cost-effective push-pull cable assembly.

PROTOTYPES

Prototypes are available and are an invaluable way to finalize the dimensional and tolerance requirements of any assembly. Life cycle and durability testing can also be conducted on prototypes, prior to production. Contact us to request a prototype.

Design

You can get started by using our design considerations or you can download our Motion Control Design Guide to help analyze, define, design and specify the most appropriate push-pull cable assembly for your specific application. The Design Guide contains useful information and technical data necessary to develop a functional and effective push-pull cable assembly. Cablecraft’s Sales and Engineering departments welcome your inquiries and can assist you with your motion control cable design project.

Design Considerations

Push applications are the most difficult to accomplish with ordinary cable assemblies because of the required column strength of the wire or cable core.

- In all but the lightest of loads, a solid wire or Armored Core must be used for pushing applications. A 1×7 or 1×19 cable may be used for very light load applications.

- The cable assembly routing in the final application needs to have as few bends or turns as possible with large, generous radii although stranded core will be more forgiving.

- Working loads should be highest in the pull direction. In the compression mode the loads need to be specified at 50% of the pull load unless using Armored Core which will yield a higher compression to tension ratio.

- The travel dimension should be limited to 2 inches or less.

- Remember that the amount of cable travel will be dependent upon the total number of bends in the system as well as the difference between cable outside diameter and conduit inside diameter. This is known as lost motion in the cable assembly.

- Cablecraft has a large number of zinc die-casted and steel swaged cable end-fittings and steel or molded conduit end-fittings to simplify your design. Custom cable and conduit end-fittings can also be considered.

- The alignment of the push-pull cable as it exits the conduit to the final attachment point must be as straight as possible.

Applications

- Throttle

- Shift

- Transmission

- Brake

- Clutch

- Engine Stop

- Steering

- Rudder

- Ailerons

- Flap

- PTO

- Choke

Why Choose Cablecraft?

With over 75 years of experience in motion control solutions, Cablecraft is a trusted partner to leading OEMs worldwide. We specialize in rugged, high-performance mechanical cable systems designed for tough environments and tight tolerances.

ISO 9001:2015 Certified

Made in the USA

Global Distribution & Support

Engineering & Prototyping Support

Engineering Resources & Design Guides

Our engineering team has applied their years of industry experience to develop resource documentation for each of our product lines.

Cable Assembly Network

Our Worldwide Cable Assembler Network can help you with your mechanical motion control solutions.

Online Catalog

Don’t need a custom design? Download our digital catalog to see all of our available cable and linkage assemblies.