Engineered for High-Performance Applications

Cablecraft’s Ball Bearing Control Cables are engineered for high-performance applications providing a highly efficient and accurate system which maximizes load capability while minimizing backlash.

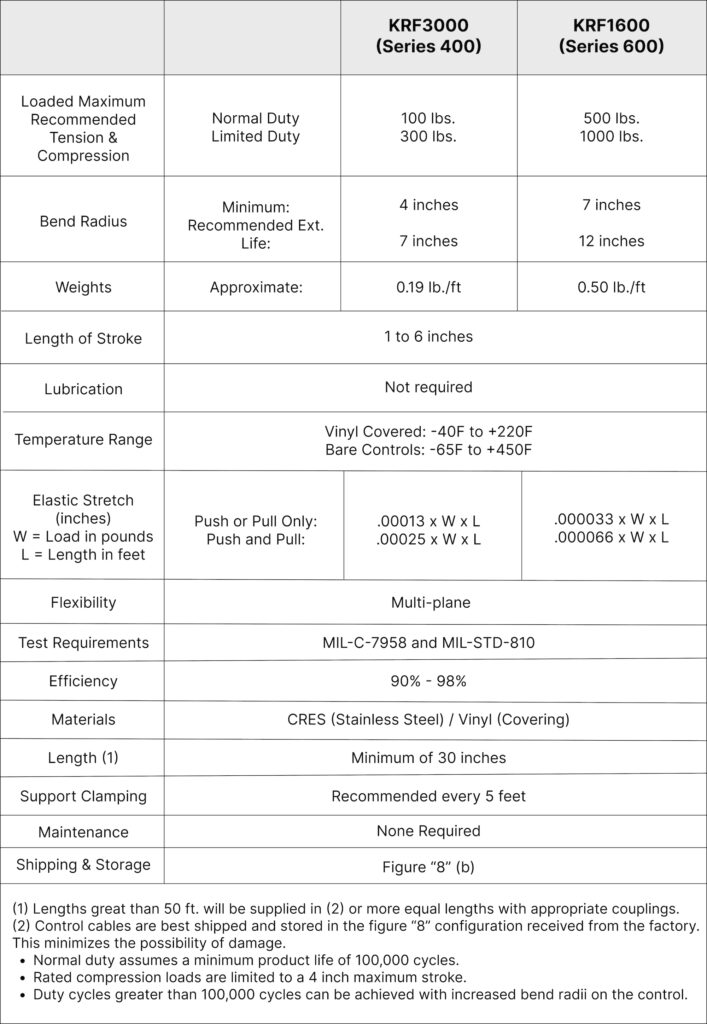

Cablecraft Ball Bearing Control Cables are available in two basic sizes. These are designated as KRF3000 (pictured) and KRF1600. Each size designates specific load and bend radius capabilities for a variety of applications.

Engineering Resources & Design Guides

Our engineering team has applied their years of industry experience to develop resource documentation for each of our product lines.

Cable Assembly Network

Our Worldwide Cable Assembler Network can help you with your mechanical motion control solutions.

Online Catalog

Don’t need a custom design? Download our digital catalog to see all of our available cable and linkage assemblies.

Key Features & Benefits

Primarily used in applications where high precision, minimal backlash, and efficient transmission of push-pull motion are required due to their ability to handle high loads and long distances with minimal friction.

Cablecraft Ball Bearing Control Cables design is enabled by several unique design features which allow the system to handle complex installations while providing the following benefits:

Key Benefits:

- Low Friction, High Efficiency: Design minimizes friction, providing smooth, responsive motion and reducing wear for extended service life.

- Wide Temperature Range: Engineered to perform in extreme conditions, our cables operate effectively from -65°F to 450°F.

- Complex Routing Up to 100+ Feet: Our cables maintain performance over long distances and through intricate routing paths, making them suitable for a wide range of industrial and aerospace applications.

- Low Lost Motion: Design ensures minimal lost motion, providing accurate and repeatable control.

- Flame Resistant: Built with flame-resistant materials, our cables meet strict safety standards for high-risk environments.

Multiple Industry - Standard End Fittings & Terminals: We offer a variety of end fittings and terminal ends to fit your specific application needs, ensuring seamless integration and reliable performance.

- All Stainless, Non-Magnetic Construction: Built with high-grade stainless steel components, our ball bearing cables are non-magnetic, corrosion-resistant, and ideal for demanding environments.

- Custom-Built to Specification: Our expert engineering team can manufacture cables tailored to your design and operational requirements, delivering customized solutions for unique applications.

- Aircraft Flight Controls

- Helicopter Flight Controls

- Engine Controls

- Marine Systems

- Industrial

Design Guide

The basic specifications for each of our control series are defined on the accompanying capabilities chart. This chart shows the basic operational characteristics for each of our control series. Load carrying capability and bend radius are the distinguishing operating characteristics between series.

The standard configurations described accommodate applications where input and/or output actions have straight push-pull motion. Rigid mounting of control cable end fittings is achieved with jam nuts and washers on the threaded portions of the main sleeves.

When required by a specific application, several options are available for sealing the control from the environment.

Engineering Resources & Design Guides

Our engineering team has applied their years of industry experience to develop resource documentation for each of our product lines.

Cable Assembly Network

Our Worldwide Cable Assembler Network can help you with your mechanical motion control solutions.

Online Catalog

Don’t need a custom design? Download our digital catalog to see all of our available cable and linkage assemblies.